The Trimble GEDO Doc system consists of the Trimble GEDO CE 2.0 track measurement trolley, the Trimble GEDO Profiler or Trimble total station and a Trimble control unit.

The system enables simple track geometry control by measuring basic quality parameters. Cant (superelevation), track gauge and twist are recorded as a function of the chainage. Measured values are shown directly in the field via live display. Important positions can be captured and coded quickly.

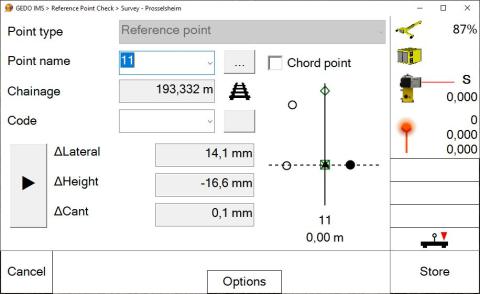

With the Trimble GEDO Profiler, the distance and height to control points can be measured, and distances to platform edges or other objects near the track can be checked.

Trimble GEDO IMS module Doc

- Capture of track gauge, cant (superelevation), and twist as a function of the chainage

- Live display of current values

- As-built check with known reference points

- Log file can be output directly in the field

Trimble GEDO Profiler

Laser measuring unit for checking track position at control points, as well as for measuring distances to objects close to the track (i.e. structures and platforms). Distances are displayed in relation to the track axis or inner edge of the rail, both perpendicularly and vertically to the cant (superelevation).

Alternatively, a Trimble total station can also be used.

- Live display and capture of basic track quality parameters

- Measurement of track gauge and cant (superelevation), as well as calculation of twist in one step

- Checking the track position at control points and measuring distances to objects close to the track (e.g. buildings and platforms)

- Coding of special track points

- Measurement of long track sections possible without full track closure and impact on train traffic

- High productivity and flexibility lowers costs and reduces personnel expenses

- Use of a universal track measurement trolley with modular expansion options

- Checking the track quality and as-built checks at reference points

- Distance measurement to objects close to the track

- Inspection before a line is put into service

- Regular condition inspection of existing lines