The Trimble GEDO Vorsys system consists of two Trimble GEDO CE 2.0 track measurement trolleys with a Trimble control unit and in combination with a Trimble total station.

The system is optimized for pre-measuring for track tamping. The measurement is based on the traditional rail alignment method, which guarantees high internal accuracy. The absolute track position is captured by measurements to control points. Deviations from the nominal track position are displayed live in the field, as well as the location of alignment transition points (main points).

The Trimble GEDO Vorsys system is used for easy-to-use and high productivity pre-measurement track tamping operations.

GEDO Vorsys

- Control of the reference point measurement and track survey utilizing the alignment method (chord measurement)

- Live display of the differences between actual and design according to track alignment

- Display of track main points

- Capturing of absolute track position with track gauge, cant (superelevation) and twist

- Special function for measuring topo points and platform edges

- Measurement to control points for variance comparison

- Optimized user guidance for track construction tasks

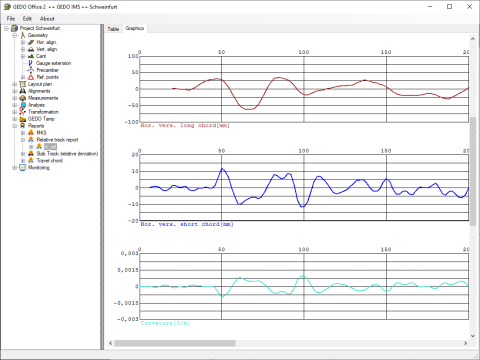

GEDO Office

- Analysis and further processing of GEDO Vorsys measurements

- Chord measurements can be re-calculated in case control point coordinates have changed

- Variance comparison between measured track and design alignment

- Analysis and data preparation for the tamping machine

- Definition of ramps at the beginning and end as well as at constraint points

- Consideration of minimum and maximum lifts as well as maximum shifts

- Output of geometry file and tamping data for tamping machine

- Formats for all well-known manufacturers (Plasser & Theurer, Matisa, Harsco Rail, Plasser American, Framafer, etc.)

- Quality reports for track position

- Comparison with previous measurement campaigns for tamping machine control

- Measurement of the three-dimensional track position, track gauge and cant (superelevation), as well as calculation of twist in one step

- Proven, recognized and reliable chord measuring principle

- Import of digital track alignment data. Checking of the track alignment data in the office software prior to starting the field work.

- Precise and reliable control of track geometry

- Extensive options for data analysis and evaluation

- Software allows a fast evaluation and transfer of tamping data to the tamping machine

- Measurement of long track sections possible without full track closure and impact on train traffic

- Flexible combination with other sensors for optimal system configuration depending on application

- Shortened construction time and reduced costs due to immediate comparison of the differences between actual and design according to the track alignment

- Pre-measurement for track tamping application

- Checking the track position before, during and after construction work

- Variance comparison for acceptance

- Inspection and documentation of track geometry