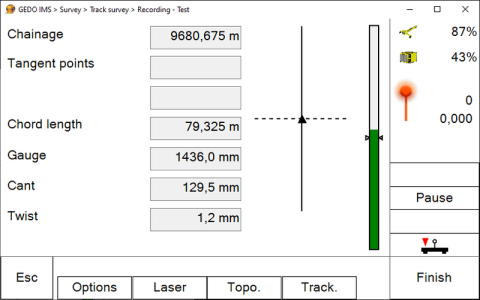

The Trimble GEDO IMS system consists of the Trimble GEDO CE 2.0 track measurement trolley, a Trimble GEDO IMU, and a Trimble control unit.

The system enables complete track geometry control. All relevant parameters such as cant (superelevation), track gauge and twist, as well as the horizontal and vertical curvature are recorded as a function of the chainage. The system is EN 13848-4 compliant.

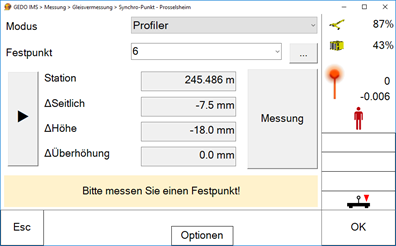

The Trimble GEDO IMS system can be extended with a Trimble GEDO Profiler. In this system configuration, distances and height differences to nearby control points, platform edges and other objects of interest close to the track can also be measured and checked.

GEDO IMS

- Control of track survey and capture of relative track geometry in combination with track gauge, cant (superelevation), and twist

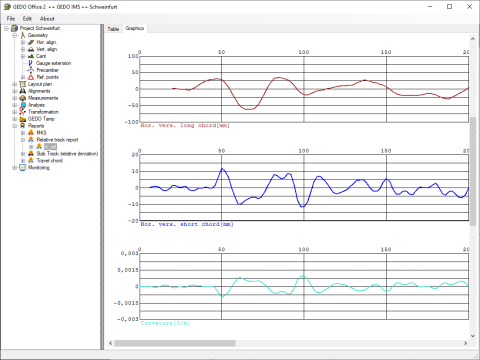

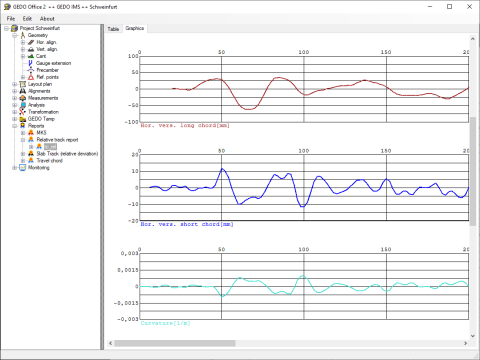

GEDO Office

- Processing of measurement data

- Calculation of horizontal and vertical curvature

- Generation of track quality protocols

Trimble GEDO Profiler

Optional laser measuring unit for checking track position at control points, as well as for measuring distances to objects close to the track (i.e. structures and platforms). Distances are displayed in relation to the track axis or inner edge of the rail, both perpendicularly and vertically to the cant (superelevation).

Trimble GNSS

The combination of the Trimble GEDO IMS system with a Trimble GNSS receiver enables geodetic positioning of the track measurement results.

- High-resolution capture of all measured values and quality parameters

- Coding of special track points

- Measurement of long track sections possible without full track closure and impact on train traffic

- Measurement of track gauge and cant (superelevation), as well as calculation of twist in one step

- High productivity and flexibility lowers costs and reduces personnel expenses

- Use of a universal track measurement trolley with modular expansion options

- Flexible combination with other sensors for optimal system configuration depending on application

- Short initialization time

- System compliant with EN 13848-4

- Inspection before a line is put into service

- Regular condition inspection of existing lines

- Use for both short and longer distances

- Measurement of relative track position for which conformity with EN 13848-4 is required