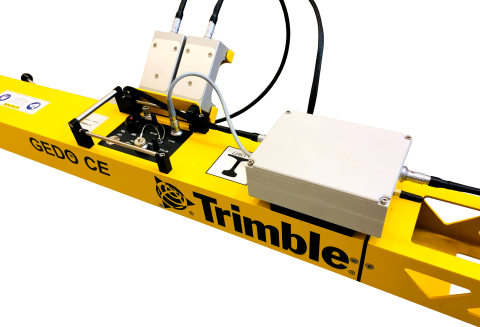

The Trimble GEDO Track system consists of the Trimble GEDO CE 2.0 track measurement trolley or electronic Trimble GEDO Track Bar with a Trimble control unit in combination with a Trimble total station. The electronic Trimble GEDO Track Bar is used for smaller projects or when a track measurement trolley cannot be used due to the construction method.

Combined with Trimble Access Rail module GEDO Track Trolley, respectively Trimble Access Rail module GEDO Track Bar software, the system provides an easy-to-use, fully integrated measurement system for highly accurate track installation, inspection, and quality control.

In a single step, the three-dimensional position of the track as well as track gauge and cant (superelevation) values are recorded. The measured data is compared with the track design alignment. Offset and correction values are displayed directly on site to enable the construction crews to adjust the track accordingly.

When used for final inspection and quality control, extensive inspection, and acceptance reports, as well as correction lists, can be generated.

The high-precision system is suitable for both conventional track and high-speed lines.

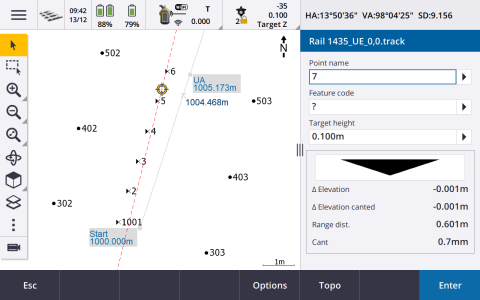

Trimble Access Rail module GEDO Track Bar and Trimble Access module GEDO Track Trolley

- Control of geodetic track survey with electronic Trimble GEDO Track Bar resp. Trimble GEDO CE 2.0 track measurement trolley

- Live display of the differences between actual and design according to track alignment

- Calculation either horizontally or in a canted (superelevated) system

- Capturing of all measurements

- For all Windows Trimble Access control units and Android Trimble Access control unit Trimble TSC5

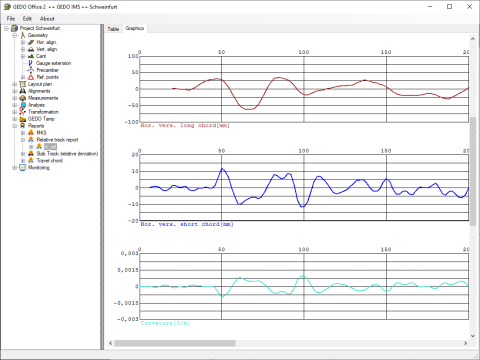

GEDO Office

- Analysis and further processing of Trimble Access Rail module GEDO Track Bar and Trimble Access Rail module GEDO Track Trolley measurement data

- Track sections taken from different station setups are merged into one resulting track

- Variance comparison between measured track and design alignment

- Quality reports for track position

- Acceptance documentation for slab tracks

- Optimization and creation of slab track correction lists

Rail inclination sensor

These sensors are used to measure rail inclination when setting up tracks and during final inspection. The rail inclination values are displayed and captured in the commonly used 1:x representation.

For users who want to use the rail inclination sensors in combination with the Trimble GEDO CE 2.0 track measurement trolley, the Windows application Trimble GEDO Track is available.

- Shortened construction time and reduced costs due to optimized setup process based on live display of the differences between actual and design according to the track alignment

- Highest precision through the primary use of the total station's directional measurement

- Measurement of the three-dimensional track position, track gauge and cant (superelevation), as well as calculation of twist in one step

- Import of digital track alignment data. Checking of the track alignment data in the office software prior to starting the field work.

- Support for gauge extensions (i.e. FAKOP® in switch areas)

- Consideration of load conditions for bridge structures or elevated structures (precamber)

- Reduced time required for documentation and acceptance measurement. Recording of the correction values and track acceptance data as well as swift protocol generation for construction companies and quality control.

- Standardized graphical and numerical reporting of correction values for lateral guidance and height correction plates

- Use with all slab track installation methods

- Control after concreting

- Determination of correction values and creation of optimized correction lists

- Final inspection before and for track release